Safety belt crash tests are a cornerstone of automotive safety engineering, playing a pivotal role in ensuring the effectiveness of safety belts in protecting occupants during collisions. These tests subject safety belts to rigorous simulations of real-world crash scenarios, providing valuable insights into their performance and reliability.

Our rigorous evaluations simulate real-world scenarios, ensuring that every belt undergoes thorough examination for durability, effectiveness, and occupant protection. Witness firsthand how our state-of-the-art facilities and expert technicians and engineers meticulously assess safety belt performance, providing invaluable insights for enhancing automotive safety standards. Trust Crash Test Center to deliver the ultimate assurance in safety belt reliability and passenger safety.

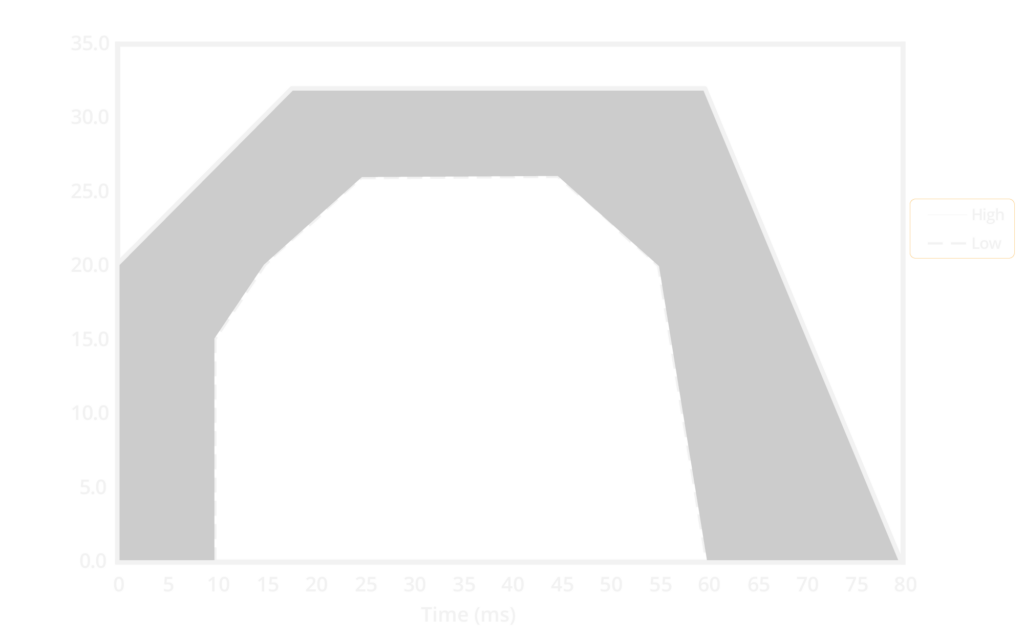

Safety belt crash tests evaluate how well safety belts withstand the forces exerted during a collision. Engineers analyze factors such as tensile strength, elongation, and durability to ensure that safety belts can endure the immense pressures of a crash without snapping or tearing. By replicating various crash scenarios, including frontal, side, and rear impacts, these tests help manufacturers design safety belts that offer consistent protection across different collision types.

The primary function of a safety belt is to restrain occupants and prevent them from being ejected from the vehicle during a crash. Safety belt crash tests assess the effectiveness of safety belts in securely holding occupants in place, minimizing the risk of severe injuries or fatalities. Advanced testing techniques, such as Compact Impact Simulator(CIS) or crash test dummies, simulate human behavior during crashes, allowing engineers to evaluate factors like belt positioning, loading patterns, and injury mitigation strategies.

Through safety belt crash tests, manufacturers can identify potential design flaws or weaknesses in safety belt systems and implement necessary improvements. This iterative process enables continuous enhancement of safety belt technology, leading to the development of safer and more reliable restraint systems. From optimizing webbing materials to refining buckle mechanisms, these tests drive innovation and advancement in automotive safety engineering.

Governments and regulatory agencies worldwide establish stringent safety standards that automakers must adhere to ensure the protection of vehicle occupants. Safety belt crash tests play a crucial role in validating compliance with these standards, demonstrating that safety belts meet or exceed specified performance criteria. By conducting thorough testing and certification processes, manufacturers can instill confidence in consumers regarding the safety of their vehicles.

Safety belt crash tests also serve an educational purpose by raising public awareness about the importance of wearing safety belts and choosing vehicles equipped with reliable restraint systems. Through media coverage and safety ratings provided by organizations such as the National Highway Traffic Safety Administration (NHTSA) and the Insurance Institute for Highway Safety (IIHS), consumers gain valuable insights into the safety credentials of different vehicle models, encouraging them to prioritize safety when making purchasing decisions.

Regulation No. 16 of the United Nations Economic Commission for Europe (UN/ECE) — covers the uniform provisions for the approval of the following and the tests applied accordingly;

The safety belt (seat belt, belt, safety belt) is a belt unit, consisting of detectable links, attached to a motor vehicle, designed to reduce the risk of injury to the user in the event of a collision or sudden deceleration of the vehicle. Such an arrangement is commonly referred to as a “belt assembly”, and the term also includes any device for absorbing energy or retracting the belt.

The Dummy to test vehicle safety belts in a simulated collision.

The dummy is specified as a testing device for ECE Regulation No. 16, “Uniform provisions concerning the approval of safety belts and restraint systems for adults of power-driven vehicles” and for EEC Directive 82/319.

The ECE R16 TNO 10 dummy device to test vehicle safety belts in a simulated collision.

The dummy is specified as a testing device for ECE Regulation No. 16, “Uniform provisions concerning the approval of safety belts and restraint systems for adults of power-driven vehicles” and for EEC Directive 82/319.

The dummy represents an adult male of the 50th percentile as regards overall size and distribution of the weight. For reasons of simplicity, the dummy does not have a forearm and only a single leg and is made of polyurethane.

Description (and comparison to the Hybrid II which it replaced).

| WHERE USED | DEFINING REGULATION | DATES |

|---|---|---|

| EuroNCAP | EuroNCAP frontal impact testing protocol | March 2004, latest: Nov 2019 |

| Frontal Collision Protection | UNECE R94 | 16 Oct 1995; Aug 12, 1996 amended 21 Feb 2002; 31 Jan 2003; 2 Feb 2007; 13 Feb 2014; 10 June 2014, 18 June 2016 |

| Head Restraints | 49CFR Part 571.202a | 72 FR 25514, May 4, 2007, as amended at 75 FR 67246, Nov. 2, 2010; 77 FR 761, Jan. 6, 2012 |

| Hybrid III Test Dummy | 49CFR Part 572 Subpart-E | 51 FR 26701, July 25, 1986, as amended at 53 FR 8765, Mar. 17, 1988; 62 FR 27518, May 20, 1997; 63 FR 45965, Aug. 28, 1998 |

| Head Restraints | 49CFR Part 571.202a | 72 FR 25514, May 4, 2007, as amended at 75 FR 67246, Nov. 2, 2010; 77 FR 761, Jan. 6, 2012 |

| Occupant Crash Protection | 49CFR Part 571.208 |

We serve our services in a short time of schedule. It gives you a time serving advanteges and getting test results faster. (Less than 10 minutes between tests!)

We are based on a important geological are.

We have state-of-the-art equipment that complies with the latest technology and regulations.